L3:Travel through Another Dimension

Part 1: Building A Slicer and Generating G Code

The grasshopper code and the slicer itself can be found at the github repo here.

Task 1: Building the Slicer

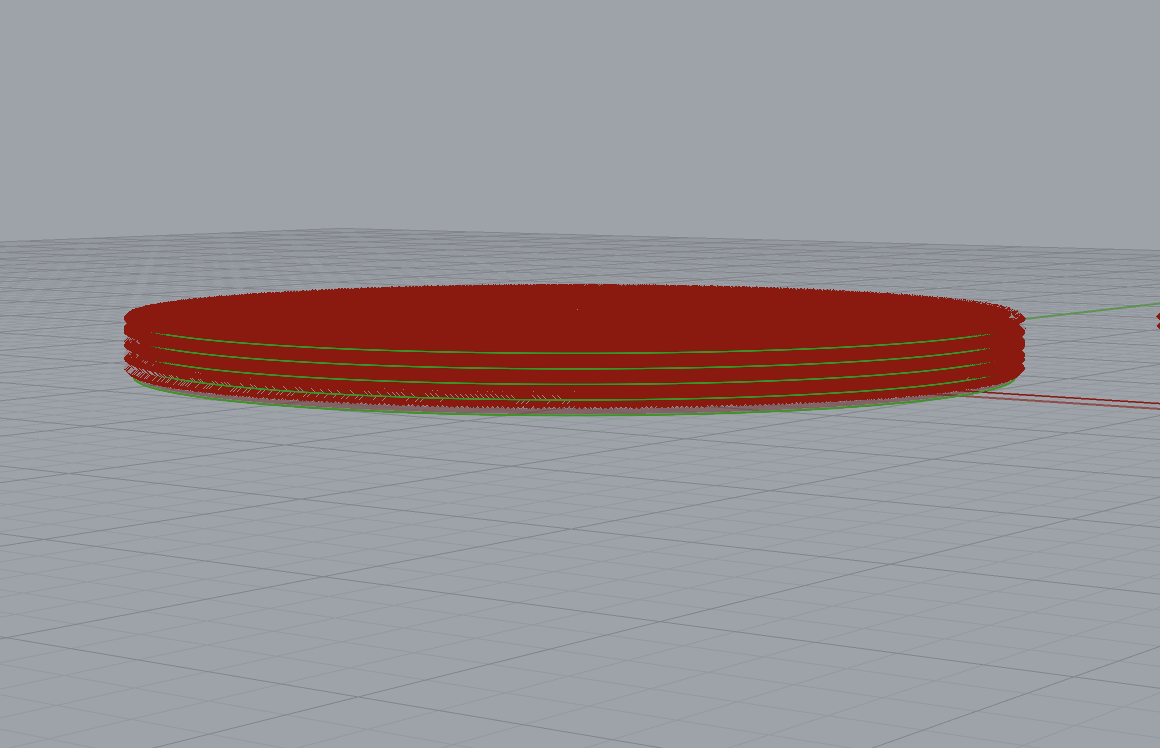

Contours of our Cylinder:

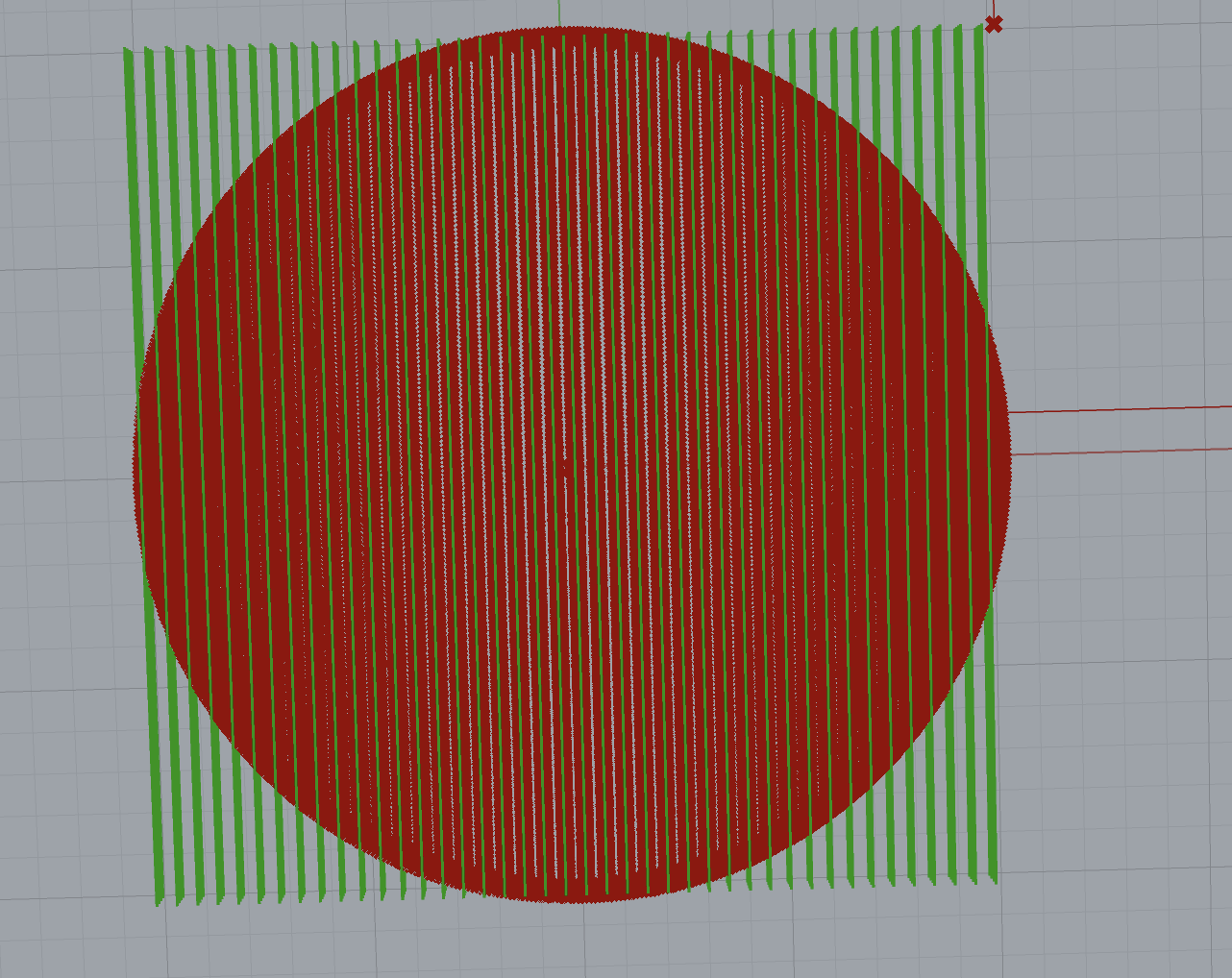

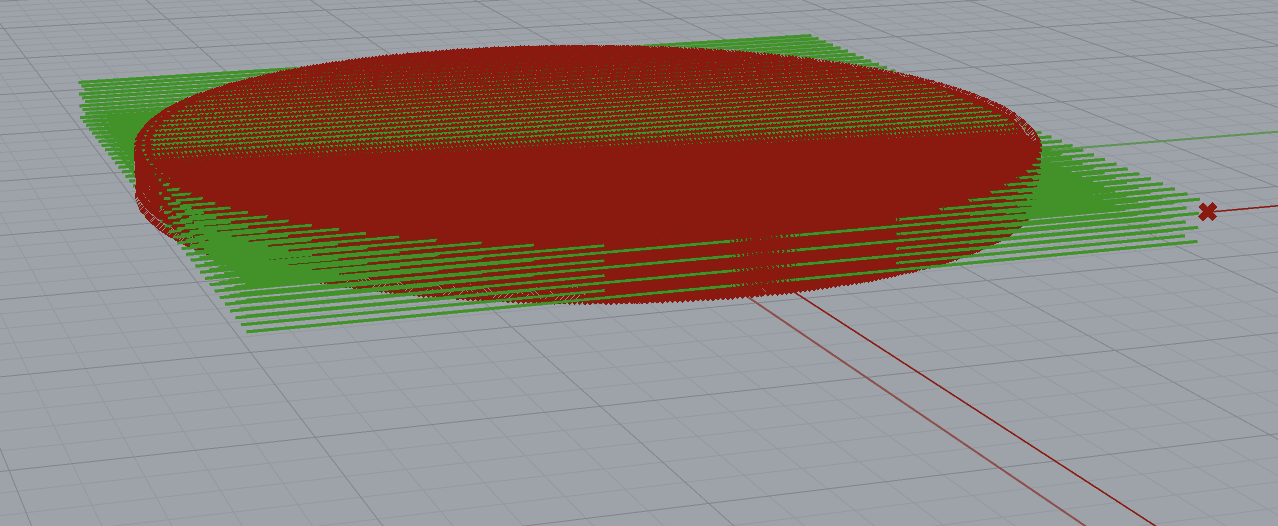

Adding the rectangular infill box:

We can see this operating at each layer:

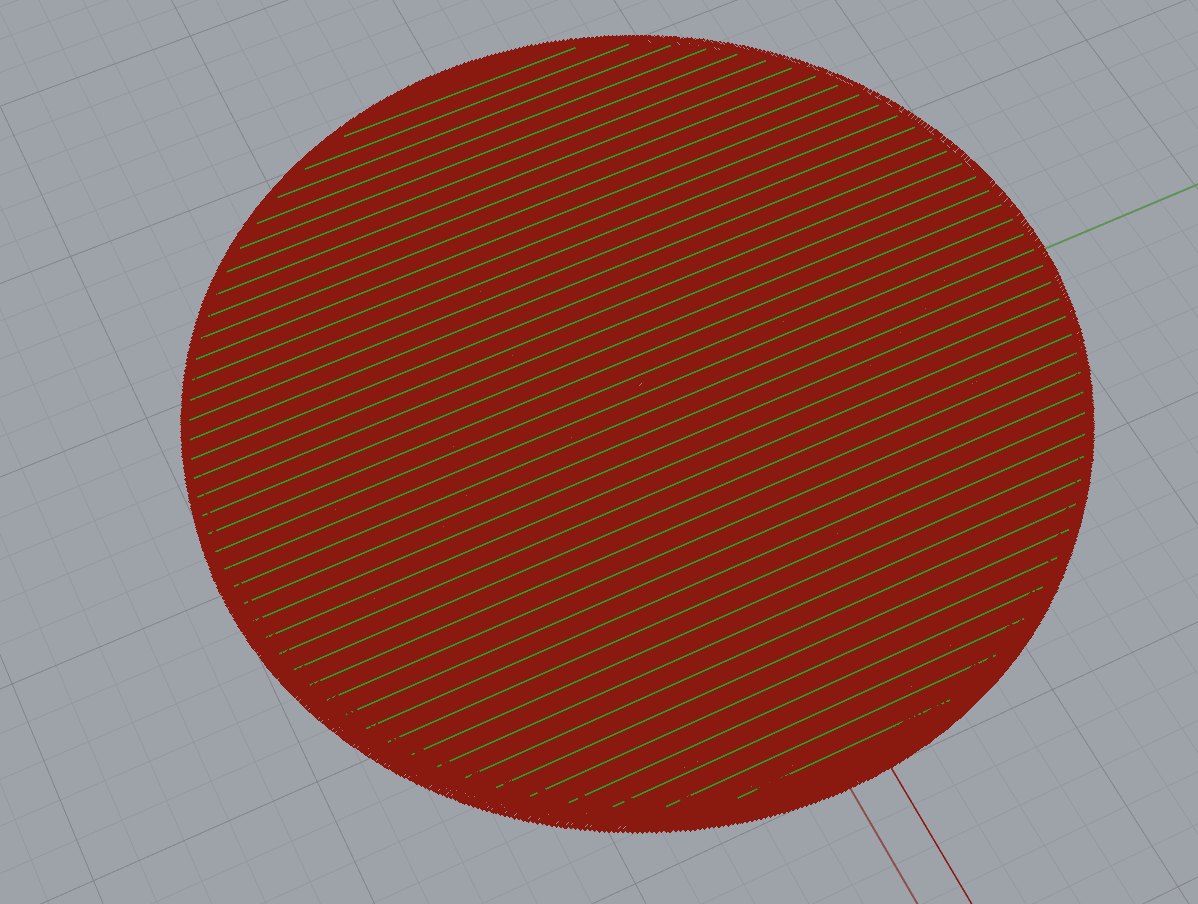

And finally with the trimmed infill lines fit to the cylinder shape:

Task 2: Generating GCode

Writing the python code was fairly straightforward - it took a few tries to get the syntax correct for some of the math functions as well as strings.

I used the following tutorial resources to look up a few python syntax questions and distance functions:

- Distance between points: https://byjus.com/maths/distance-between-two-points-3d/

- Python sqrt syntax: https://realpython.com/python-square-root-function/

- python join list syntax: https://www.w3schools.com/python/gloss_python_join_lists.asp

The output gcode is here

Task 3: Validating GCode

The code has not passed all tests yet. I still need to fix the following before moving on to Part 2: 22/3/2024 @ 21:21:26 ⇒ Running 25 Tests On “output.gcode” …

- [PASSED] Test 1: Is Correct Printer Model [MK3S].

- [PASSED] Test 2: Is Correct Printer Nozzle Size [0.4 mm].

- [PASSED] Test 3: Set Units to Millimeters.

- [PASSED] Test 4: Use Absolute Coordinates for X, Y, Z.

- [PASSED] Test 5: Use Relative Distances for Extrusion (E).

- [PASSED] Test 6: Set Valid Extruder Motor Current [LQ: 538, HQ: 430].

- [PASSED] Test 7: Set Max Accelerations [X: 1000, Y: 1000, Z: 200, E: 5000 mm/s^2].

- [PASSED] Test 8: Set Min Bed Temperature [60 C].

- [PASSED] Test 9: Set Hotend Temperature for PLA [200 C - 225 C].

- [PASSED] Test 10: No Cold Extrusion / Set Hotend Temp Before Extrusion.

- [PASSED] Test 11: Home All Axes (X, Y, Z) at Beginning of Print.

- [FAILED] Test 12: All X Positions Within Bounds [0 mm, 255 mm] at line 35.

- [FAILED] Test 13: All Y Positions Within Bounds [-4 mm, 212.5 mm] at line 147.

- [PASSED] Test 14: All Z Positions Within Bounds [0 mm, 210 mm].

- [PASSED] Test 15: All Z-Moves Are Independent (No X, Y, E).

- [PASSED] Test 16: Travel XY Feed Rates (No Extrusion) Within Limits [0 mm/min, 12000 mm/min].

- [PASSED] Test 17: Print Feed Rates (Extrusion) Within Limits [0 mm/min, 7200 mm/min].

- [PASSED] Test 18: Z Feed Rates (Layer Change) Within Limits [0 mm/min, 720 mm/min].

- [FAILED] Test 19: Extrusion Values Are Sane for Filament Diameter [1.75 mm] and Nozzle Diameter [0.4 mm] at line 36.

- [PASSED] Test 20: No Extrusion at Z < Min Layer Height [0.15 mm].

- [PASSED] Test 21: All Layers in Increasing Z-order / No Crossing Previously Printed Z Heights.

- [PASSED] Test 22: Turn Off Hotend Temperature At End of Print.

- [PASSED] Test 23: Turn Off Heated Bed Temperature At End of Print.

- [PASSED] Test 24: Disable Fan At End of Print.

- [PASSED] Test 25: Disable Motors At End of Print. 22/3/2024 @ 21:21:26 ⇒ Finished Test Run on “output.gcode” (Passed 22 of 25 Tests).

The code is now successfully running - I need to adjust the calculation for v_out and ensure I had proper float validation checks.

Additionally, I had to update the code to move to the center of the build plate.

Part 2: Fabricating the Design

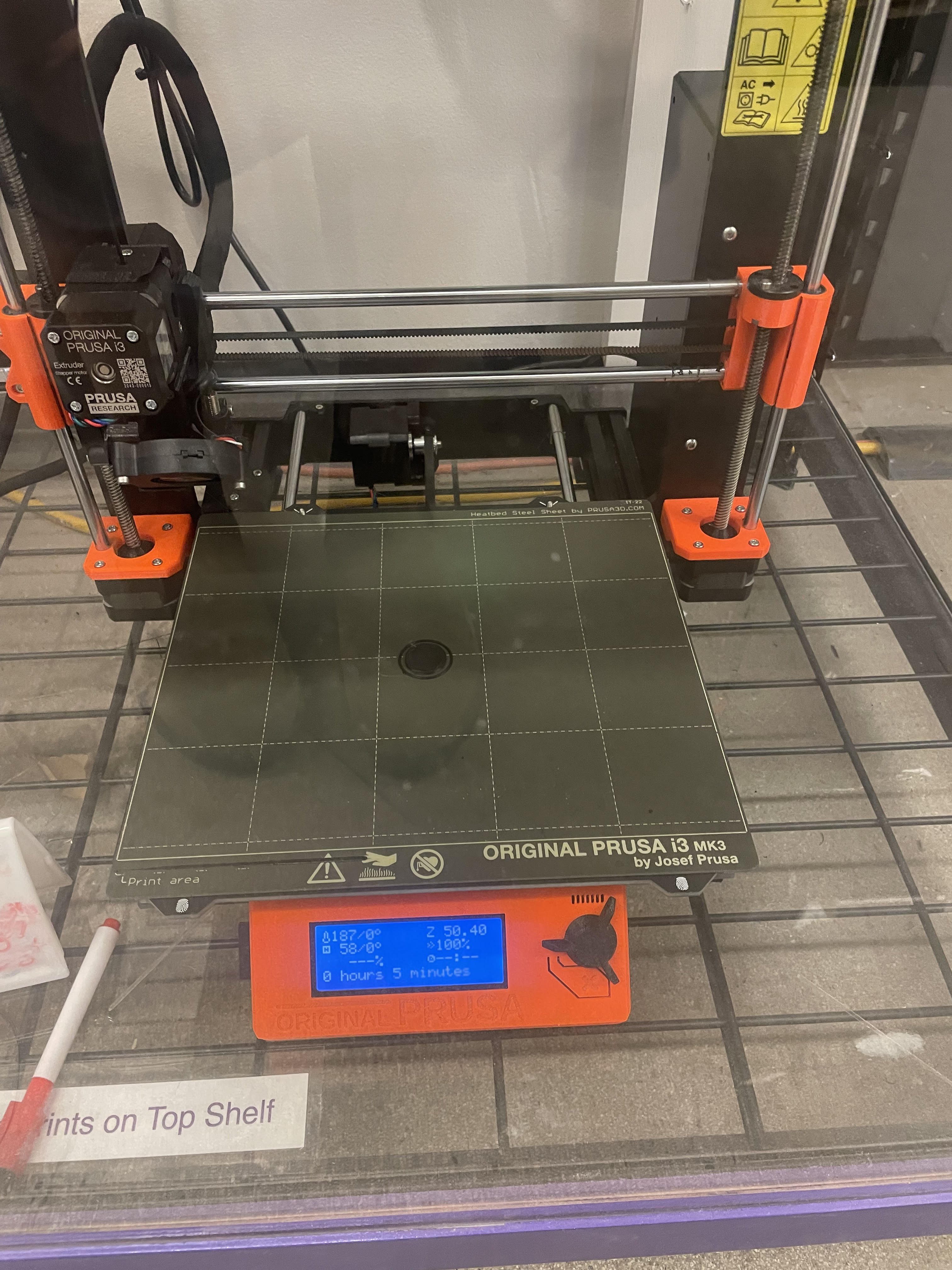

I fabricated the test cylinder both with my custom slicer/Gcode generator and the .stl provided on the course website with Prusa slicing.

The resulting cylinders look almost identical. I did notice that the print time was longer for the custom slicer/Gcode variation - it took 11 minutes to print while the class version took 5. Additionally, the printer extruded material while doing the initial move to the center of the build plate.

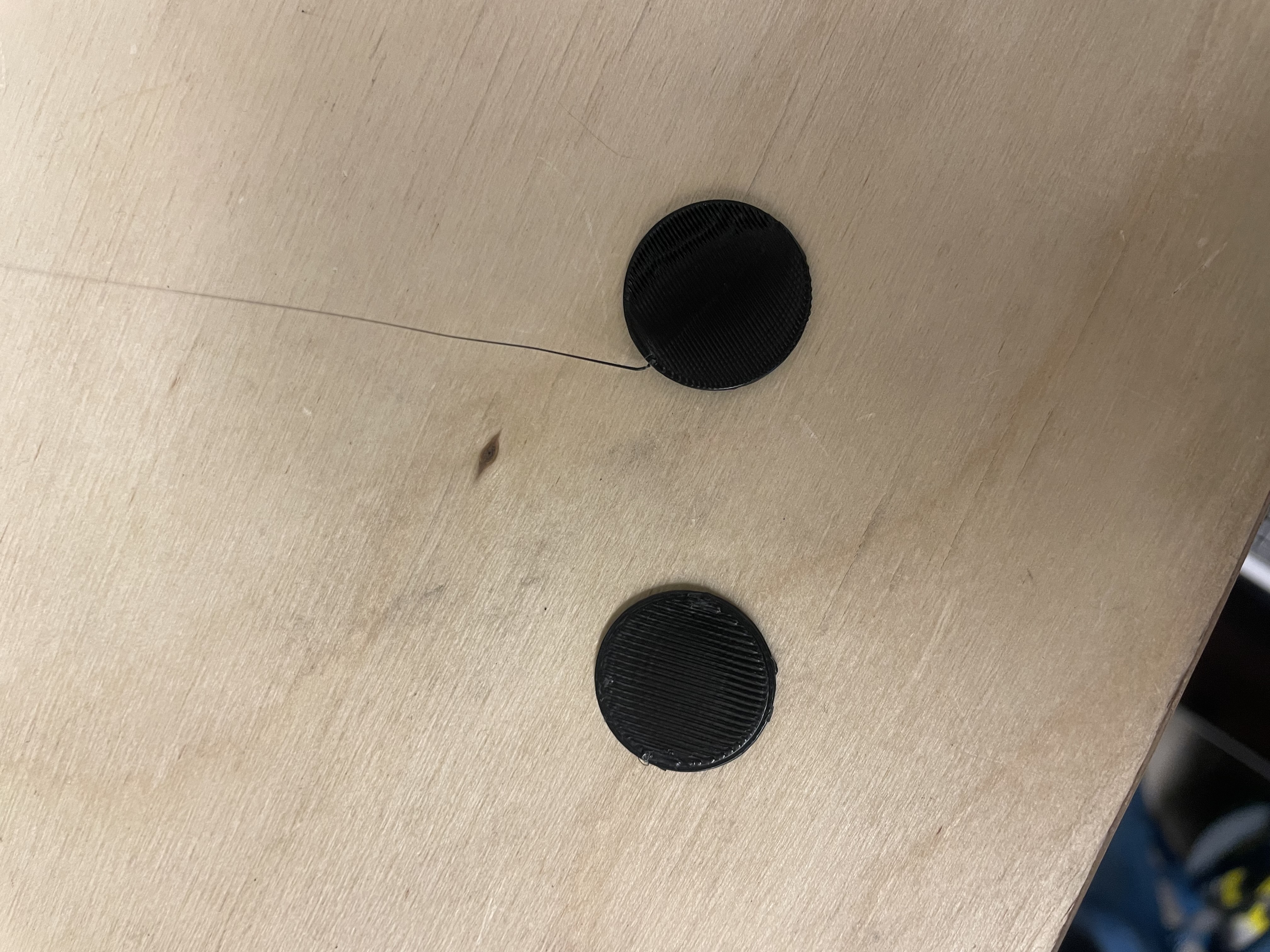

Side by Side (excess material can be seen on the print from the custom slicer: